- Home

- Products

- Air Bubble Film Machine

- Compound PE Air Bubble Film Machine

Bubble Wrap Extrusion Plant

(Laminated air sealed film sheet extrusion line)

Introduction

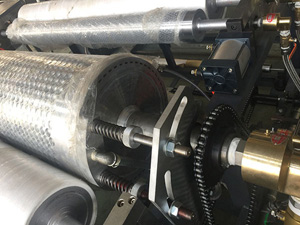

The bubble wrap extrusion plant is composed of seven main parts: the extrusion mechanism, vacuum bubble forming mechanism, trimming mechanism, waste recycle system, leveling mechanism, winding mechanism and electrical control system. It is generally used to produce 3-5 layers of bubble film, and it can be customized to a maximum of 7 layers of composite bubble film with a wide range of applications.

Compared to a traditional bubble film machine, this machine features an additional extruder, a compound mechanism, and two feeding racks. The entire machine operates automatically in order to adapt to the production of multi-layer composite bubble film.

During production, the machine features automatic operation. It is easy to operate, and features a stable performance with a low investment cost and high speed production.

Applicable raw material

Main raw material: low density polyethylene (LDPE) with melt index MI=2~7;

LLDPE with melt index MI=1.0~1.5 in proper proportion;

Regenerated LDPE with melt index MI=2~4 can be used partly or wholly to make a certain width bubble film.

Parameters

| Model | JDFPE-1600B | JDFPE-1600C | JDFPE-2000B | JDFPE-2000C |

| Main extruder | Φ80mm | Φ80/70mm | Φ90mm | Φ90/80mm |

| Auxiliary extruder | Φ60mm | Φ70mm | Φ70mm | Φ80mm |

| Product’s width | 1600mm | 1600mm | 2000mm | 2000mm |

| Yield | 150KG/Hour | 200KG/Hour | 180KG/Hour | 250KG/Hour |

| Working linear speed | 25M/min | 35 M/min | 25 M/min | 35 M/min |

| Main motor power | 30KW | 30KW/22KW | 45KW | 45KW/30KW |

| Auxiliary motor power | 15KW | 22KW | 22KW | 22KW |

| Total power | 156KW | 225KW | 182KW | 284KW |

| Power supply | 380/3/4/50 (Volt/Ph/Line/Hz) |

380/3/4/50 (Volt/Ph/Line/Hz) |

380/3/4/50 (Volt/Ph/Line/Hz) |

380/3/4/50 (Volt/Ph/Line/Hz) |

| Sizes | 17000´5500´4100mm | 17000´5500´4100mm | 17000´6500´4100mm | 17000´6500´4100mm |

Applicable raw material

1. A side suction roller can be used to achieve more uniform cooling and inspiration.

2. It can be equipped with high quality die heads in order to further improve product quality. While ensuring that the width of the die is easily adjusted, the pressure inside the die is not changed, and the uniformity of the film thickness is thus ensured.

3. The unwinding mechanism can be equipped with an automatic deviation correction device.

-

Contact

- Add.:

NO.399 Gangkou Avenue, Ruian Economic Development Zone, Ruian City, Zhejiang Province, China - Tel.: +86-577-65159968

- Mobile: +86-13736929666

- Email: jd@jiandajx.com

- Add.:

-

Products

-

About Us

Jianda Machinery Co.,Ltd. is a plastic-processing machinery manufacturer in China, primarily engaged in the developing and manufacturing of air bubble film extrusion machine, stretch film extrusion machine, plastic thermoforming machine, lamination extrusion machine

Read More